What is a Flat Sheet Laser Cutting Service Good For? Find Out!

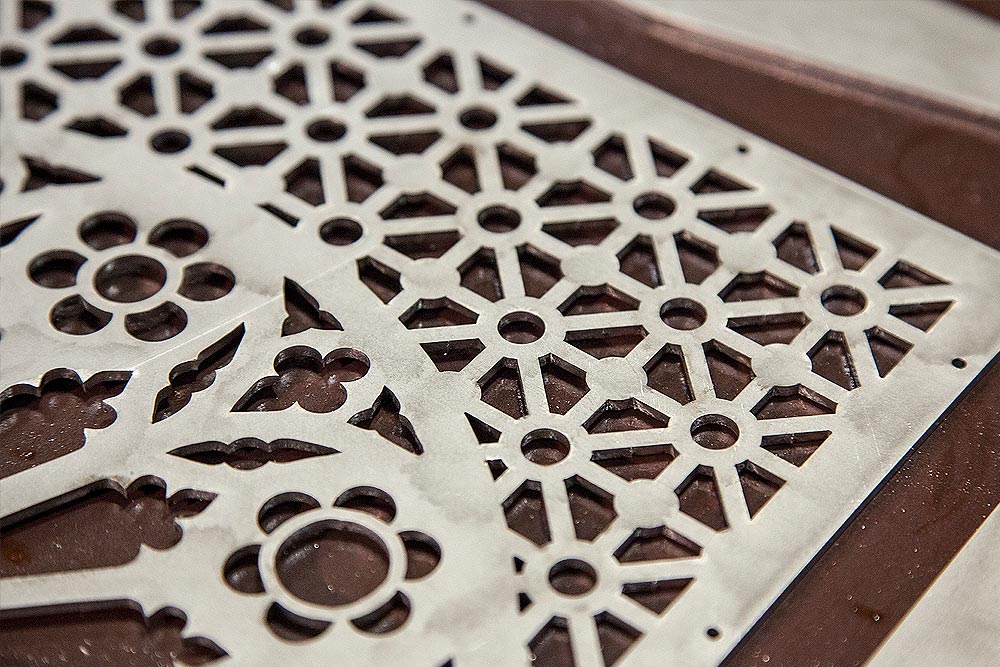

While there is no one single cutting technology that can serve all purposes, flat sheet laser cutting is a smart option for a variety of applications. Among the many technologies for producing metal parts, flat sheet laser cutting offers a powerful combination of benefits compared to water jet, plasma cutting and other methods.

At BenCo Technology, our top-of-the-line flat sheet laser cutting service ensures optimal results when cutting flat components and parts. Keep reading to learn more about our flat sheet laser cutting services and see why this technology is ideal for producing simple parts from flat sheet steel, stainless steel, brass, copper, aluminum and other metals.

When You Need Precision

Our flat sheet laser cutting service allows us to produce parts accurately and quickly. Thanks to our equipment’s advanced computer-controlled operation, we can ensure consistency on even the highest volume jobs and produce precise parts from the first piece to the last. And because laser beams can’t wear down, the edges produced by our laser cutting service are more refined, cleaner and of higher quality compared to those produced with traditional cutting methods.

When You Need Speed

Flat sheet laser cutting can deliver optimal results in record time – even with parts that have extra features and complex shapes. Whether a full run or a single prototype, our flat sheet lasers can make markings, etch, add holes, slots and part numbers, cut and more simultaneously, so you can receive the finished components you need without the need to spend additional time waiting for more processes to produce the same results.

When Cost is a Consideration

Thanks to the speed in production, complex nesting software and the elimination of secondary manufacturing steps, flat sheet laser cutting can ultimately save your company time and money over the life of your project. Regardless of the number of components you need, flat sheet laser cutting can meet even the most demanding timelines. What’s more, since you don’t need to put your parts through additional manufacturing processes to add holes and marks, refine or etch them or something else, you can essentially save money and eliminate the need for additional expenses as well.

Ready to Learn More?

Thanks to our state-of-the-art flat sheet fiber lasers, we can cut large quantities of parts precisely and quickly. Whether you need a full run of thousands of parts or a single prototype to test your design, our team can meet your specifications in record time. If you have any questions about our flat sheet laser cutting services or you’d like to speak to our team about the cutting technology that’s best-suited for your next project, contact us today. We look forward to hearing from you!