MIG, TIG & ROBOTIC WELDING

Strong Joints & Perfect Cuts for Your Metal Parts

In order to serve as a one-stop shop for our clients, our laser cutting and metal fabrication campus is also home to the latest welding technology. We have a full line of Miller MIG and TIG welders that are calibrated annually for quality assurance, and also offer robotic welding for precise runs of high-volume parts.

We can handle carbon steel, aluminum and stainless steel, and our employees are AWS Certified for unlimited thickness with both carbon steel and aluminum. If you’re interested in learning more about our standard and robotic welding capabilities, contact us today.

- MIG & TIG WELDING

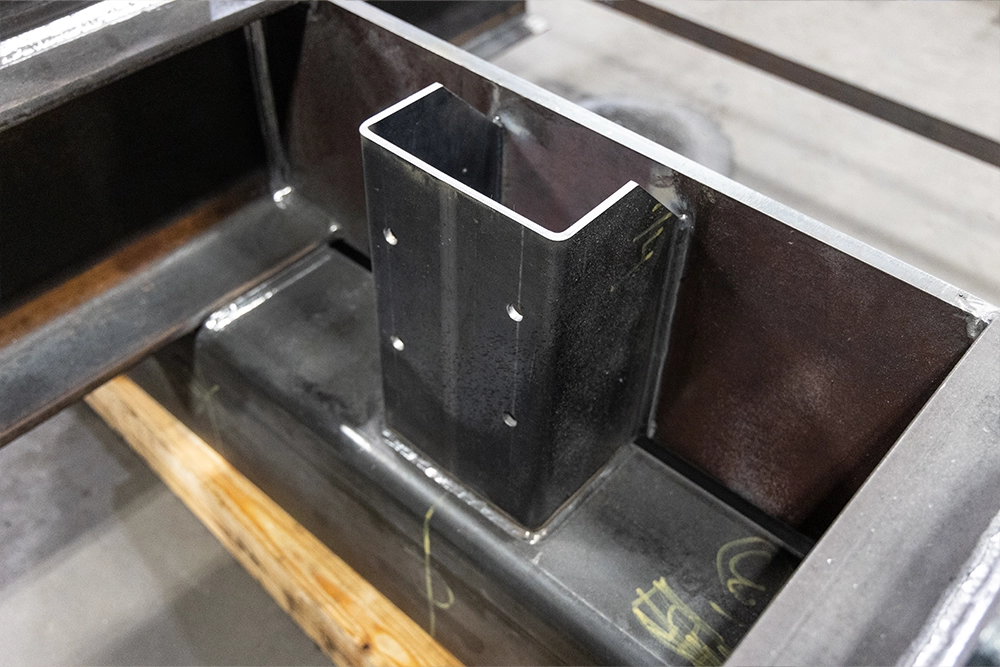

Our AWS Certified technicians can build components using mild steel, carbon steel, stainless steel and aluminum. They are certified for unlimited thickness, and are experienced at reading drawings, building fixtures and ensuring the highest quality outcomes for your parts. - ROBOTIC WELDING

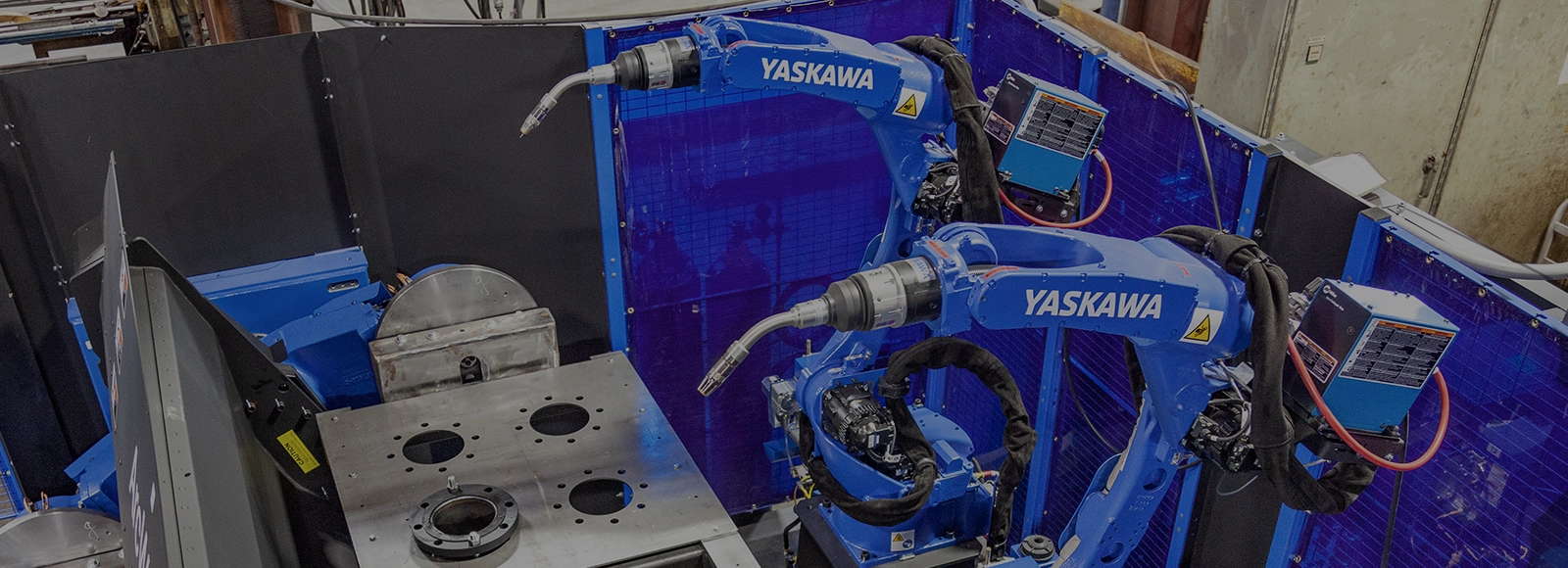

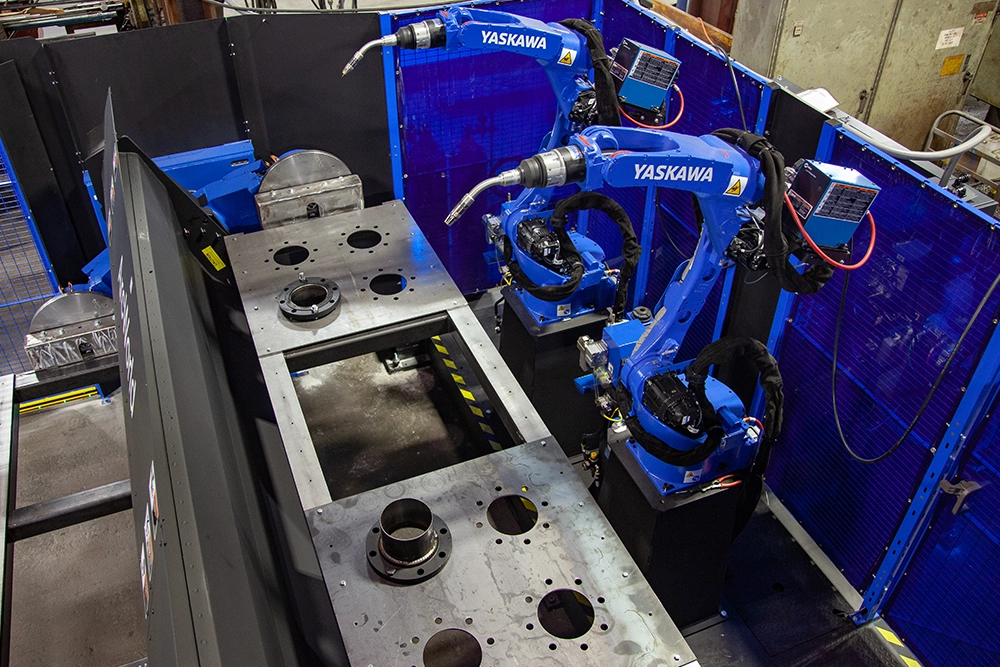

With a Yaskawa/Motoman Arcworld system that includes two MIG welding robots within a 37″ by 113″ enclosure, we can quickly and precisely weld a wide array of parts and components up to 1,650 lbs. per station. Whether your base material is mild steel, carbon steel, stainless steel or aluminum, our robots work quickly to deliver high-quality projects at 0.002″ repeatability for both Tack Welding or Full Weld out Procedures.

In addition to AWS Certification, our experienced welding team is trained to read blueprints in order to ensure the highest quality parts made exactly to specification. In order to create consistent quality, we’ll even design and build weld fixtures for your parts depending on the size and frequency of your order. Unsure which type of welding technology is the best fit for your project? Our Project Managers can analyze your parts, make the best recommendation, and then see the job through from start to finish.

Best of all, thanks to our full suite of laser cutting, fabrication and finishing equipment, our staff can expertly handle any project in any quantity from single prototypes to full production runs. So if you’re looking for a metal fabrication partner that can cut, form, weld, finish and assemble your next order, please contact us today.We look forward to working together with you!