Water Jet Cutting Even the Heaviest of Parts

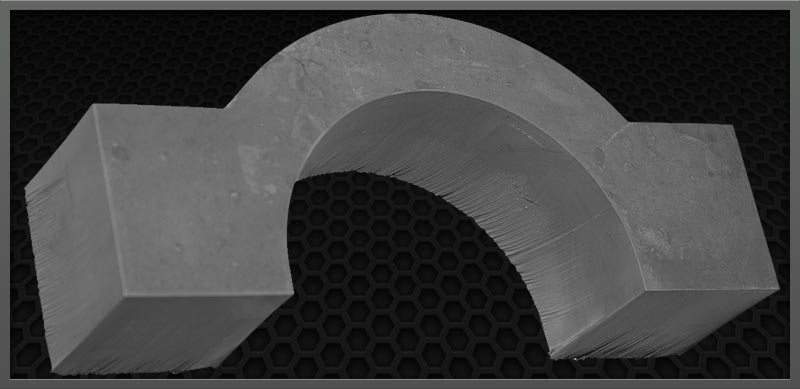

With our PA water jet cutting service, we can create heavy-duty parts out of really thick materials. In the case of the part shown below, our water jet shop turned out 6” thick slugs that went on to become parts for an industrial machine.

After a little bit of additional machining and finishing, these parts were used to support a huge spindle in a critical manufacturing application. And water jet cutting was the best way to create the thick, high-strength parts that were specified by the project’s engineer. By cutting slugs on our water jet which were then sent on for finishing, we saved our client time, money and effort.

Thanks to more than 60,000 pounds per square inch of pressure, our water jet uses a pinpoint stream of water and sand to cut even the thickest materials. So when you need a thick, heavy part like this one, we can deliver.

A few important benefits of water jet cutting include:

- the ability to cut individual sheets ranging from thin glass to 6″ thick steel and stone

- the ability to cut stacks of materials up to 8″ thick

- the ability to cut a variety of materials, including steel, aluminum, stone, glass, rubber, plastic and even paper

- the ability to cut brittle materials thanks to a low-pressure piercing function

- the ability to cut thick, heavy-duty parts for critical applications

If you’re interested in learning more about our water jet shop, please contact us today! We’d be happy to fill you in on the unique benefits that this fabrication machine provides and discuss how we might be able to help you with your next project.