Precision Quality Control Systems and Inspection Services

Our Advanced CMM & 3D Analysis Capabilities Will Ensure the Tight Tolerances Your Business Needs

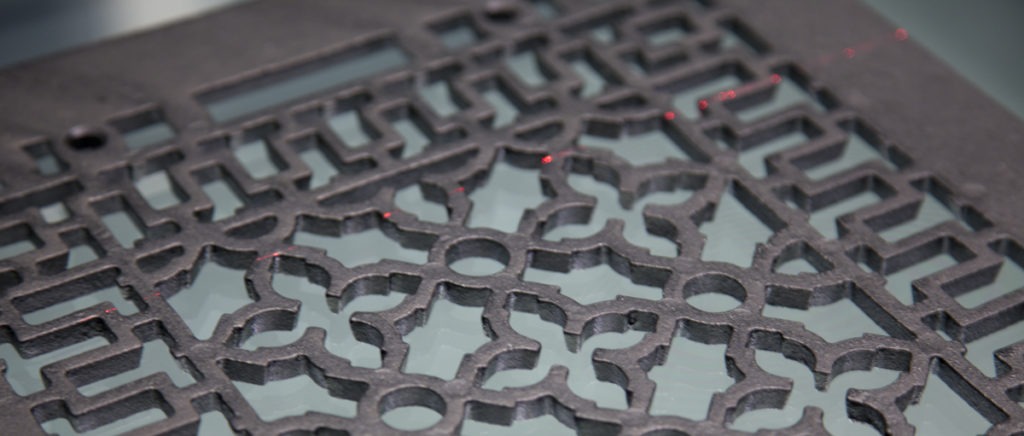

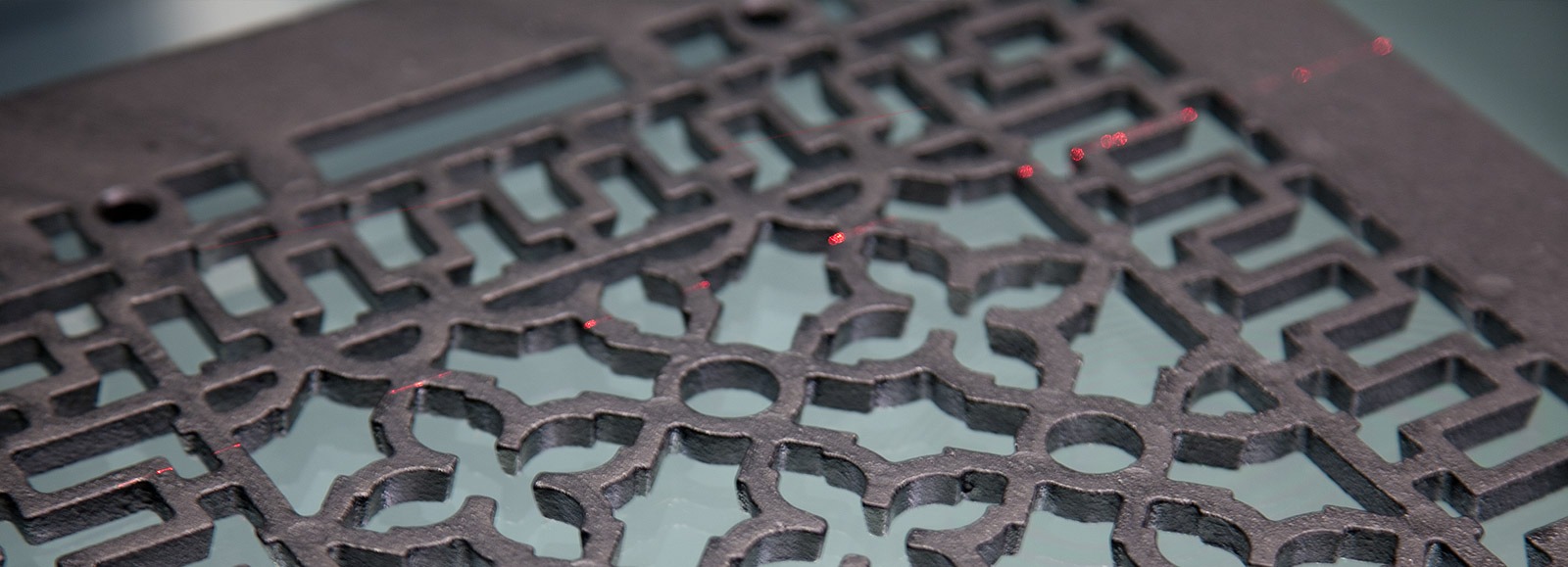

Our approach to quality is a part of everything we do at BenCo. Whether we’re designing, laser cutting, or fabricating a new part for a customer, or in any other phase of the production process, our eye is always on quality, precision, and our QC system and process.

At BenCo, we support our customers in a number of ways and one of our most common and critical roles is QC.

Our approach to quality control – whether as a part of a full project or when we’re hired to provide inspection services – is rooted in three primary areas of focus; our certifications, capabilities and procedures.

Certifications

BenCo’s Reading and Honey Brook, PA facilities are both certified to ISO 9001:2015 standards. We strictly comply to ISO standards with quality and precision and have incorporated these standards into our processes.

Capabilities

At BenCo, we house several quality control scanners and lasers that allow us to precisely verify that the parts we cut are on spec.

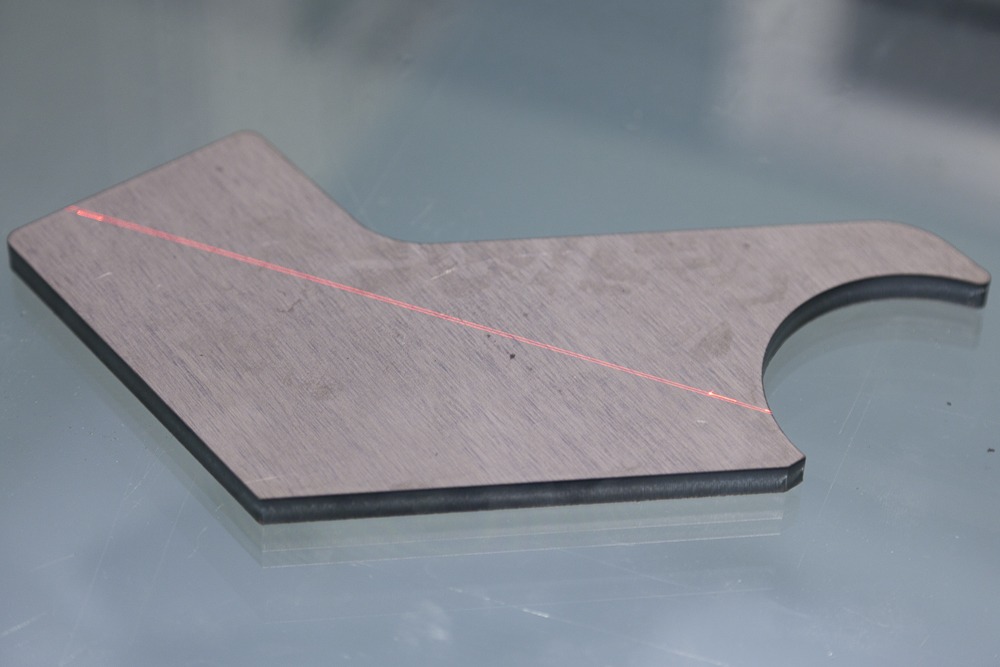

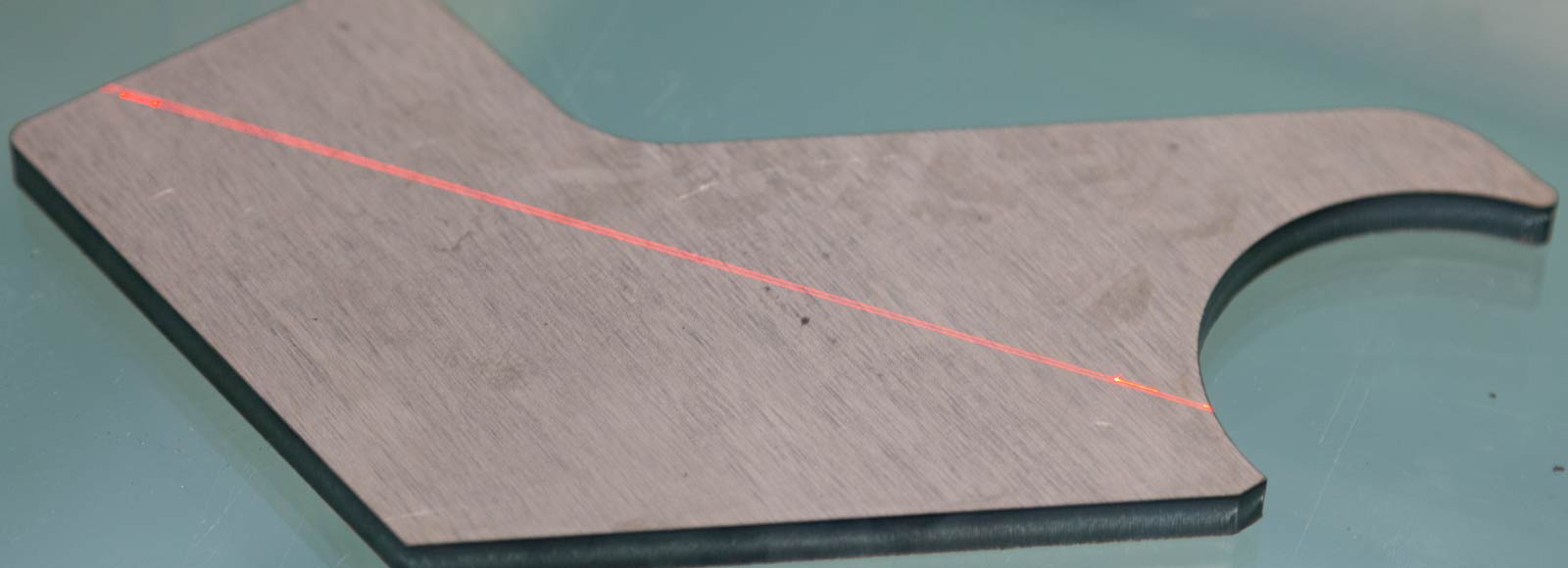

We use our in-house Hexagon CMM (coordinate measuring machine) and an advanced PolyWorks Inspector 3D analysis and QC solution to measure and verify your parts’ dimensions.

The technology we have in place along with our skilled team of project managers allows us to help our customers design and build high-quality, precise parts and products.

We provide this level of QC support in a number of ways.

- Reverse engineer flat parts from existing samples

- Create precise, ready-to-use .DWG or .DXF files from existing parts as needed

- Compare a run of parts to their drawing to verify tolerances

- Create and print a pass/fail inspection report showing actual deviation

- Ensure the quality and accuracy of a set of parts based on precise CMM readings

Procedures

As an ISO 9001-certified manufacturing facility, strict quality procedures are inherent in how we run our quality system and services. We have established procedures that provide consistent inputs with the goal of also receiving predictable outputs.

Procedures are a vital part of our Continual Improvement process and give us a starting point from which to make changes and improve our product.

Quality Control & Inspection Services

Our QC team can help supplement your own quality control systems and add another layer of assurance of the quality of your products before you ship.

The degree of accuracy we’re able to achieve and confirm throughout our QC system is a service we also offer to businesses looking for third-party certification of their part’s tolerances.

Our inspection services include verification of your parts against approved drawings with our Hexagon PolyWorks laser scanner. You’ll also receive a dimensional report to take to your customers to further validate the quality of your parts on delivery.

Whatever your QC needs – from full-service design through inspection services to quality support services for third-party parts validation, we can support projects of all sizes and complexities.

Contact us today to learn more about our quality control and inspection services and how we can support your next project.